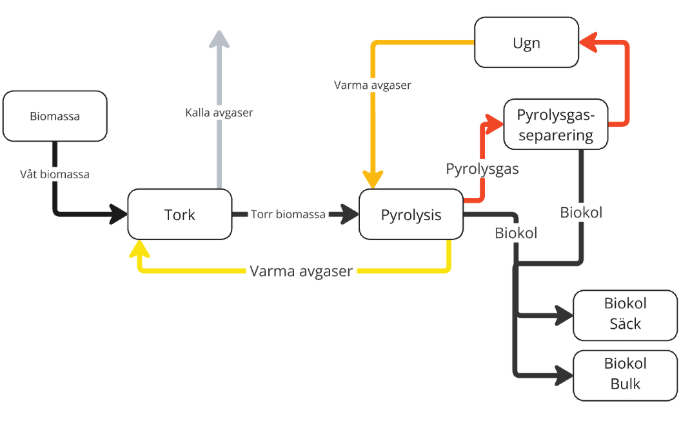

The Biochar Production Process

Biochar is produced through a process called pyrolysis, in which biomass is heated in an oxygen-free environment at temperatures between 400 and 600°C. During this process, the biomass decomposes without combustion, resulting in two main products: biochar and an energy-rich pyrolysis gas.

Step 1: Biomass Drying

Before pyrolysis, the biomass is dried in a rotary drum dryer to increase energy efficiency. This step reduces moisture content, minimizing the energy needed for the subsequent pyrolysis stage.

Step 2: Pyrolysis

The dried biomass is then fed into the pyrolysis drum, where it is gradually heated to 400–500°C, depending on the desired biochar quality. During heating:

🔹 Part of the biomass converts into pyrolysis gas, a combustible gas, rich in energy.

🔹 The remaining solid material becomes biochar, retaining much of the original carbon.

Step 3: Energy Recovery from Pyrolysis Gas

The pyrolysis gas is directed to a purification stage, where fine biochar particles are removed. The purified gas is then used as fuel in a separate combustion chamber, generating heat energy.

This heat is recycled back into the process, powering both the pyrolysis reaction and biomass drying, making the production process highly energy-efficient and self-sustaining.

Step 4: Cooling and Packaging

Once pyrolysis is complete, the biochar is cooled to prevent self-ignition. The finished biochar is then packaged in bulk bags or containers for further use, such as:

✅ Soil enhancement – improving fertility, water retention, and carbon sequestration.

✅ Industrial applications – replacing fossil coal in sectors like steel production and water purification.

This closed-loop system ensures maximum efficiency, minimal emissions, and a highly sustainable biochar production process.